RAKING AND TEDDING

Raking and tedding plays a vital role in the grass harvesting process. The speed and time saving is essential for optimal quality of the product to be collected.

MAXIMUM FLEXIBILITY

The hay Top 300 offers great performances in tedding and raking. It is design for small and medium farms.

RELIABILITY

All the Enorossi products are built for unmatched reliability.

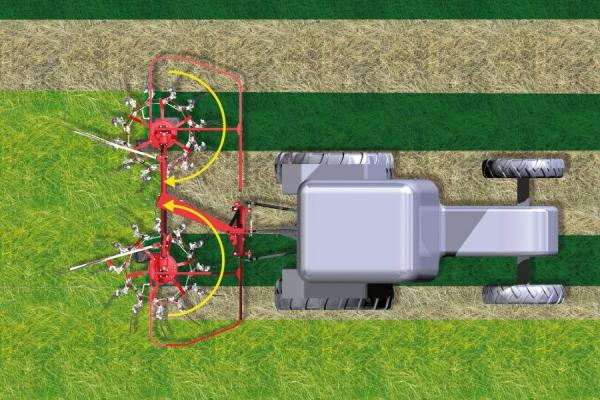

The TOP 300 is tedder-rake combinations with adjustable tines that are kept in the horizontal working position by centrifugal force.

This TOP 300 combines high capacity with clean working, even in the heaviest crops.

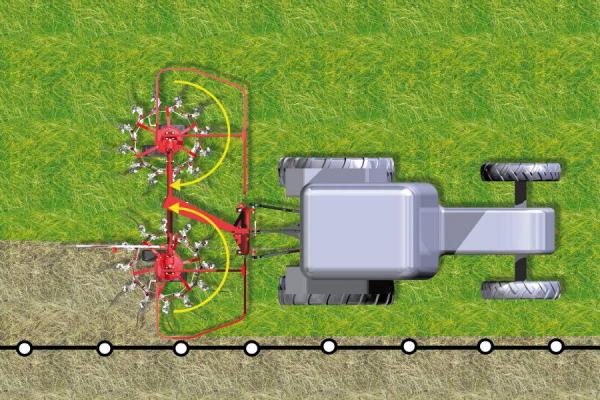

The TOP 300 follows the path of the tractor in turns, without damage the swath, thanks to the pivoting headstock. When lifted, the machine automatically locks in the central position for safe handling on slopes.

PERFECT GROUND FOLLOWING CAPABILITIES

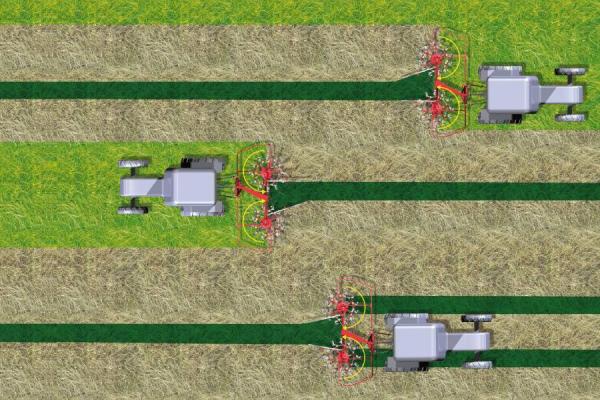

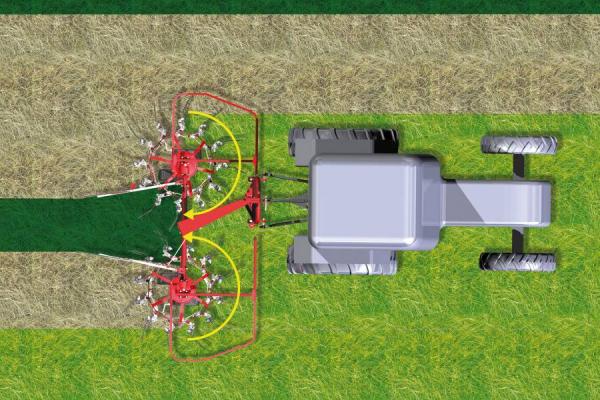

The TOP 300 follows the tractor dependably over rough field conditions, thanks to their moveable link brackets. The wheels are angled forward towards the front of the rotors and close to the tines. This ensures that not only the wheels, but also the tines, smoothly follow ground contours. The machine forms a windrow in the central position. The machine provides exceptionally clean raking, even at high working speeds, and produces a loose, fluffy windrow. The windrow width can be adjusted with the crop deflectors. Clean separation from the spread crop allows windrowing across the full working width of 300 cm (9’10”). When working in light crops, it is possible to form a double windrow in three passes. The crop deflectors on the TOP 300 have two height settings.

The TOP 300 moves the crop perfectly. The uniform spreading is due to the horizontal positioning of the tines working in combination with the crop divider. Normally crop deflectors are fully open when tedding. Along field boundaries and ditches, however, the deflector should be moved inward to prevent crop loses.

Български

Български English

English